Popular high-temperature protection film that the house lover admits to be number 1.

Popular high-temperature protection film that the house lover admits to be number 1.

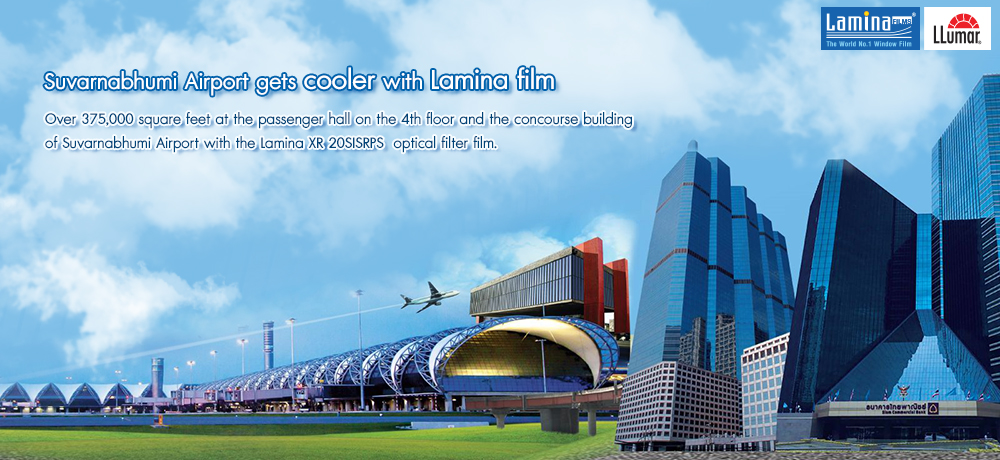

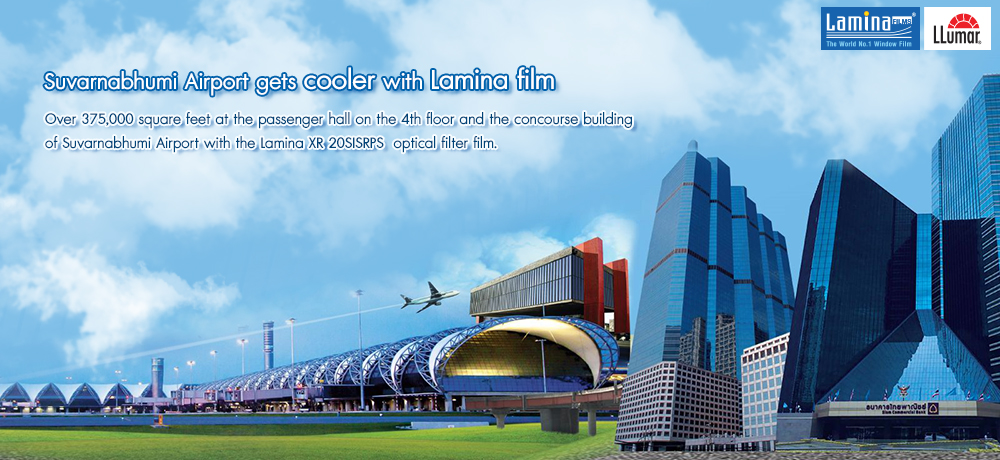

Building Films LLumar Top Series Popular high-temperature protection film

that the house lover admits to be number 1

With Nano Metallic Sputtering + UV Absorber reduce the heat from the sun more than 70%, protect more than 99% UV, prevent splinters of glass fragments.

9 reasons to film the building "La mina Lamar"

The most popular is no. 1

Reduce the heat from the sun by up to 70%

prevents UVA, UVB rays that cause 99% of skin freckles and skin cancer

Reduce the stress of the eyes from over 90% glare to feel comfortable throughout the day.

Reduce electricity bills and reduce air conditioning operation.

Reduce the fragmentation of glass fragments and reduce the chance of theft

Airy, provide privacy. Not obstructing external visibility

Slow down the deterioration of furniture. And home appliances

Scratch-resistant coating for easy care There are many film versions to choose according to the owner's style.

Make the house and building always look as shiny and new. 7 years long warranty.

| Film |

Color |

% daylight thermal cut |

% light transmittance |

% UV transparent |

% reflectance |

| TOP45NXSRPS |

Natural Sky |

49 |

44 |

99 |

11 |

| TOP35BKSRPS |

Light Sky |

51 |

34 |

99 |

10 |

| TOP20CSRPS |

Deep Clound |

48 |

21 |

99 |

8 |

| TOP20RBGSRPS |

Natural Green |

56 |

20 |

99 |

8 |

| TOP05BKSRPS |

Deep Earth |

60 |

10 |

99 |

8 |

| TOP05NSRPS |

Natural Earth |

70 |

12 |

99 |

32 |

| TOP45NXSRPS |

| Color |

Natural Sky |

| % daylight thermal cut |

49 |

| % light transmittance |

44 |

| % UV transparent |

99 |

| % reflectance |

11 |

| TOP35BKSRPS |

| Color |

Light Sky |

| % daylight thermal cut |

51 |

| % light transmittance |

34 |

| % UV transparent |

99 |

| % reflectance |

10 |

| TOP20CSRPS |

| Color |

Deep Clound |

| % daylight thermal cut |

48 |

| % light transmittance |

21 |

| % UV transparent |

99 |

| % reflectance |

8 |

| TOP20RBGSRPS |

| Color |

Natural Green |

| % daylight thermal cut |

56 |

| % light transmittance |

20 |

| % UV transparent |

99 |

| % reflectance |

8 |

| TOP05BKSRPS |

| Color |

Deep Earth |

| % daylight thermal cut |

60 |

| % light transmittance |

10 |

| % UV transparent |

99 |

| % reflectance |

8 |

| TOP05NSRPS |

| Color |

Natural Earth |

| % daylight thermal cut |

70 |

| % light transmittance |

12 |

| % UV transparent |

99 |

| % reflectance |

32 |

| Model |

Tone |

% daylight thermal cut |

% light transparent |

% UV transparent |

Shading coefficient of film |

% reflectance |

Solar energy transmission cost |

| XR20SISRCD/PS |

Dark silver |

79 |

15 |

99 |

0.24 |

60 |

12 |

| XR15GOSRPS |

Gold |

78 |

15 |

99 |

0.25 |

50 |

12 |

| XR15BSRCD/PS |

Bronze |

76 |

8 |

99 |

0.28 |

18 |

9 |

| XR15GSRCD/PS |

Dark gray |

74 |

7 |

99 |

0.29 |

13 |

9 |

| XR15GNSRPS |

Dark green |

73 |

16 |

99 |

0.31 |

32 |

14 |

| XR15BLSRPS |

Dark Blue |

72 |

12 |

99 |

0.33 |

18 |

18 |

| XR35SISRCD/PS |

Silver |

68 |

28 |

99 |

0.36 |

44 |

22 |

XR20SISRCD/PS

Dark silver

|

|

XR15GOSRPS

Gold

|

|

XR15BSRCD/PS

Bronze

|

|

XR15GSRCD/PS

Dark gray

|

| |

|

|

|

|

|

|

XR15GNSRPS

Dark green

|

|

XR15BLSRPS

Dark blue

|

|

XR35SISRCD/PS

Silver

|

|

|

| Model |

Tone |

% daylight thermal cut |

% light transparent |

% UV transparent |

Shading coefficient of film |

% reflectance |

Solar energy transmission cost |

| XP35BSRCD |

Bronze |

63 |

37 |

99 |

0.43 |

25 |

28 |

| XAN20NSRPS |

Smoke |

60 |

22 |

99 |

0.46 |

25 |

27 |

| XR50SISRPS |

Crystal Blue |

54 |

47 |

99 |

0.53 |

27 |

37 |

| XD30GNSRPS |

Green |

54 |

30 |

99 |

0.53 |

15 |

32 |

| XAP35NSRPS |

Smoke |

52 |

35 |

99 |

0.55 |

19 |

35 |

| XAP60GNSRPS |

Crystal Green |

44 |

57 |

99 |

0.64 |

14 |

48 |

| XAP50NSRPS |

Smoke |

44 |

48 |

99 |

0.64 |

13 |

48 |

XP35BSRCD

Bronze

|

|

XAN20NSRPS

Smoke

|

|

XR50SISRPS

Crystal Blue

|

|

XD30GNSRPS

Green

|

| |

|

|

|

|

|

|

XAP35NSRPS

Smoke

|

|

XAP60GNSRPS

Crystal Green

|

|

XAP50NSRPS

Smoke

|

|

|

Components of the Lamina LLumar building film

- Special adhesive layer (Mounting Adhesive) with the properties of special adhesive layer secures polyester and in the molecular level together with the windshield to help prevent danger from windshield splitting (Shattering).

- Top grade polyester film (1st layer), metal coating and UV absorbance (Metallized Polyester Layer containing UV Absorbent) comes with the properties to reduce heat by almost 80%, prevent ultra-violet (UV) radiation for more than 99%

- Laminating Adhesive Features, a layer of adhesive bonds polyester film layer 1 and layer 2 together.

- Excellent quality polyester film layer (2nd layer) comes with the properties to help increase heat reduction efficiency, toughness, and durability.

- Scratch-resistant layer, ultra-translucent crystal type, the copyright only the factory produces Scratch Resistant Coating. The feature prevents the film to be scratched to maintain the functionality and beauty for a long time.

- All models of Lamina LLumar are made from premium polyester coated with heat-absorbing particles, UV Absorbent and special glue to hold the windshield molecules, The safety film provides excellent protection against shattering, shading coefficient as low as 0.24 and various performance specifications are tested in accordance with standards, AIMCAL approaches (Association of Industrial Metallizers Coaters and Laminators) and ASHRAE to become the only building film provider in Thailand certified ISO 9001.

The idea of solar energy. Solar energy consists of 3 types of radiation: 53% infrared (IR) radiation, 3% ultraviolet radiation, and 44% light. Heat generated by sunlight, by infrared radiation and combined light infrared radiation is only a part of the sun. They are invisible with the naked eye but the heat is present. In general, excellent quality films, such as Lamina LLumar, could prevent more than 90% of the infrared radiation. The heat reduction test (which has a % of reduction in infrared radiation combined with a % reduction in heat) should be measured from direct sunlight to get the correct results. The measurement of the heat from the spotlight and the different heat source has completely different components as in the following table.

| Radiation type |

sunlight |

spotlight |

| ultraviolet radiation (100 - 400 nm) |

3% |

Very less |

| infrared ray (700 - 2400 nm) |

53% |

80 - 90 % |

| illumination (380 - 780 nm) |

47% |

10 - 20 % |

| ultraviolet radiation (100 - 400 nm) |

| sunlight |

3 % |

| spotlight |

Very less |

| infrared ray (700 - 2400 nm) |

| sunlight |

53 % |

| spotlight |

80 - 90 % |

| illumination (380 - 780 nm) |

| sunlight |

47 % |

| spotlight |

10 - 20 % |

Therefore, testing tinted film at the reduction of heat from the spotlight or the light from the infrared ray tube will give higher value from sunlight as the light from the spotlight, including infrared rays, has a higher amount of infrared radiation in the sunlight, which the tinted film would reduce the amount of infrared radiation. The following graph that shows the % value of thermal cut to be the most accurate heat reduction percentage.

Summary of the approaches to consider the value of % reduction of heat before selecting or purchasing tinted film are

1. The % reduction in heat from the overall light must be defined, not just infrared radiation or values measured from spotlights.

2. Heat reduction % value must be the standard test by ASHRAE and AIMCAL.

TOP05BKSRPS

TOP05BKSRPS